Footwear industry

The footwear industry is the main consumer of Invisible Pen, being used in more than 80% of factories in the country. OTB UV markers are used in several stages of footwear production, from cutting and sewing to applying halogen.

1. Automatic CAD cutting and scoring machine

It is possible to use OTB technology in all brands and models of automatic cutting machines. Use the Invisible Pen replacements to mark, to illuminate, install the 1.20 m UV lamps on the Power Lumini line on the front and back.

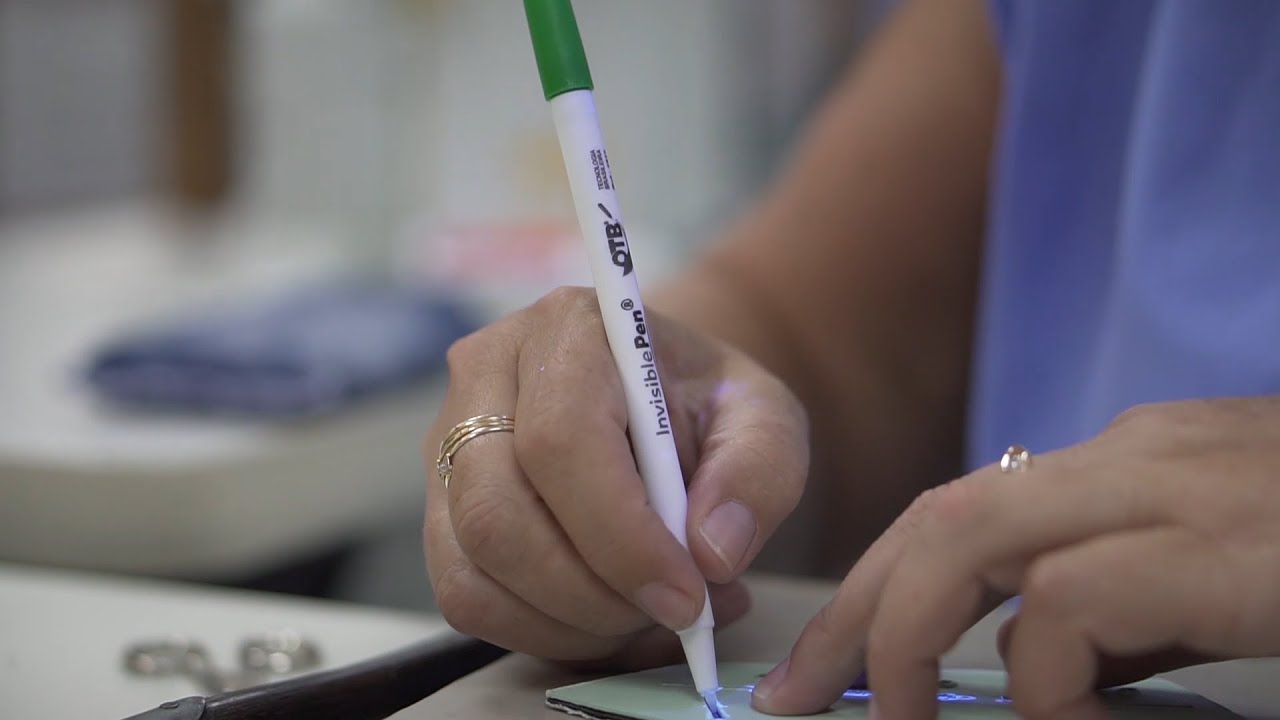

2. Manual shaving on seedlings

For manual scratching on templates, both invisible felt-tip pens and metal-tipped ballpoint pens can be used. This choice depends on the characteristics of the materials, thus delivering incredible results that are far superior to the conventional method.

3. Preparation of parts for sewing

The Invisible Pen inks combined with the UV Power Lumini OTB lighting devices, allow a perfect visibility of the spiders in the glue of the piezas, offering to the workers a greater precision and speed in their work.

4. Sewing machine

The marked Invisible Pen OTB is perfect for use with sewing machines. Use a UV LED device with a magnet and flexible rod that allows a perfect adjustment of the light focus on the needle bar.

5. Scratching - Outsole contour

The Invisible Pen OTB allows you to draw the contour of the areas manually or with a pneumatic machine with perfect efficiency of visibility of the spiders.

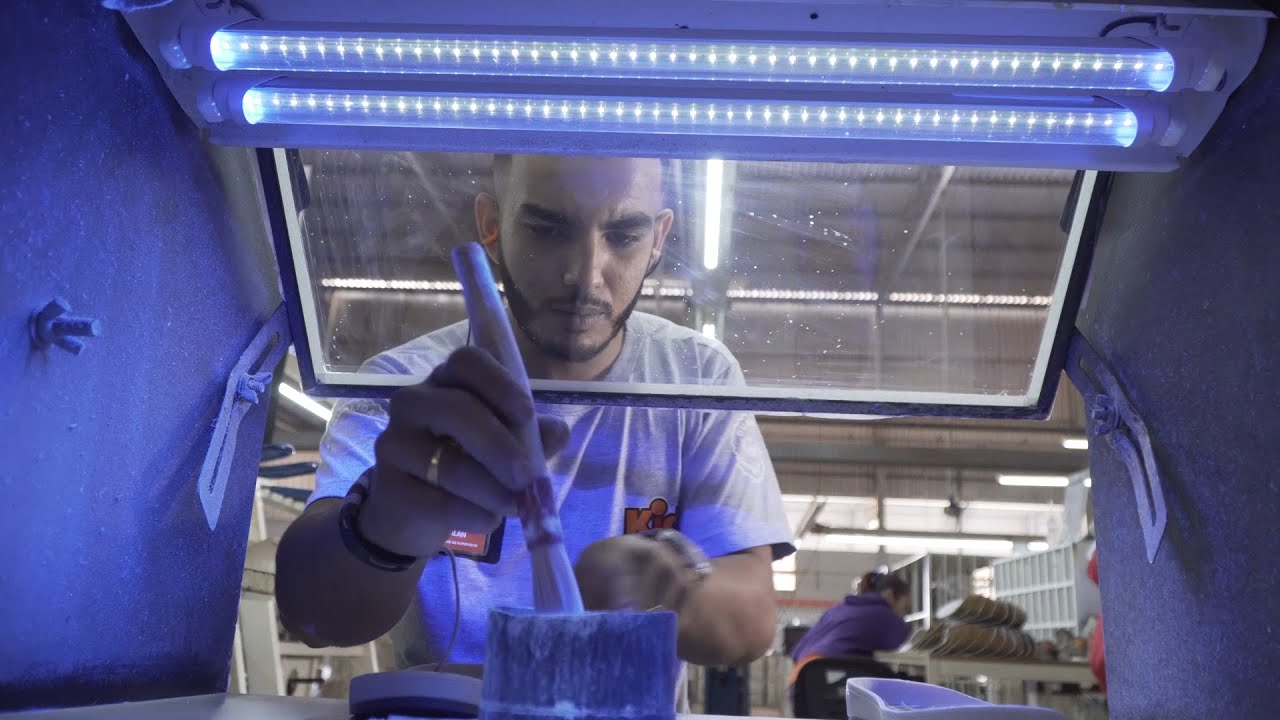

6. Sanding / Ripping

Using the UV LED on the sanding machine allows a perfect fit on the sanding roller or wire brush, with great lighting efficiency, providing more efficient scratch visibility and greater precision when sanding, exactly at the edge of the marking .

7. Halogen Application

Power Lumini OTB devices allow operators to have greater security and conditions to check, through UV light, possible failures in the application of halogen, delivering a perfect job, without waste or failures.

8. Application of adhesives on the sole/upper

OTB technology contributes to the application of adhesives to the upper and sole with perfection. Offers optimal lighting efficiency to visualize invisible marking and check for adhesive application failures.

The excellent visibility provides a uniform and precise application, avoiding more than 90% of possible failures, such as stickers above or below the scratches, significantly improving the quality of the operation.

9. Gluing the sole

Power Lumini OTB devices provide operators with a perfect view of the invisible marking, in addition to providing conditions to verify and correct flaws in the application of the adhesive and adhesives that are above or below the marking, resulting in a great quality product.